Packo RSA Services

Packo RSA and its dealers can offer you the best milking and milk cooling solutions in and around South-Africa.

If you need any service, advice or simply a small replacement part, please contact Packo RSA directly or contact your local dealer.

Many replacement parts can also be found in our webshop, where you can shop 24/7.

Besides general milking and cooling advice, Packo RSA is highly experienced in Parlour planning.

Because of the exclusive cooporation with the Packo-Fullwood Group in Belgium, we sell worlds best parlours in South Africa and around. At Packo RSA, Each detail of a milking parlour is carefully considered. We install 4 different milking parlours:

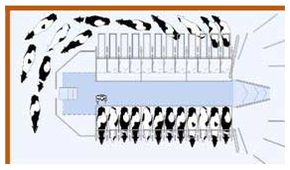

Rotary Parlours

Revolution II

The Revolution II provides the most efficient use of space giving maximum cow numbers in a circle.

The main features of this milking system are:

- Quick installation

- Simple, robust design

- It is quick to load up the cows and udder presentation is excellent

- There is an option for slow milkers to go round twice

- Available with or without feeding

- The rotary can run clockwise or anti-clockwise

- Is fully integrated with Fullwood Crystal herd management software.

Resulting in many benefits for the farmer:

- Low running costs due to long life and low maintenance requirement

- Large groups of cows can be milked very quickly

- Ability to personalise the rotation speed and direction, feeding and other features to suit you and your herd

- Safe, operator-friendly environment to help attract and retain the best herdsmen – safe for the operator, safe for the animal and safe for the product.

The Merucry

The main features of this milking system are:

- The rotary incorporates a galvanised steel structure and a reinforced concrete cow standing platform

- High cow throughputs compared with static milking systems

- The herringbone design of stalls allows clusters to be attached from the rear or side to suit user preference

- The rotary can run clockwise or anti-clockwise

- Is fully integrated with Fullwood Crystal herd management software

Resulting in many benefits for the farmer:

- Low maintenance costs

- Stress-free environment for both cow and operator

- Reduced milking time will free up time for herd management and other farm duties

- Perfect cow positioning for excellent milking performance

Herringbone Polours

Fullwood design and manufacture two different Herringbone parlours:

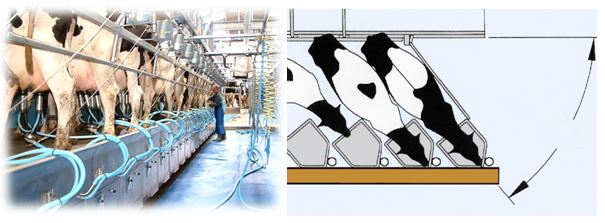

The 50°

The 50° herringbone was designed specifically for rear leg milking. The cows stand nearer to the operator and the increased angle of the cow standing improves udder presentation allowing quick cluster attachment. Indexed breast rail locates each cow in the optimum milking position.

Other features and benefits include:

- Wider walkways provide quick, cow-friendly entry and exit.

- Shorter pit reduces walking distance and reduces operator work routine.

- Twin rump rail for operator safety

- Adjustable rear entry gate for each batch of cows

- Individual mangers available for in-parlour feeding

- Is fully integrated with Fullwood Crystal herd management software

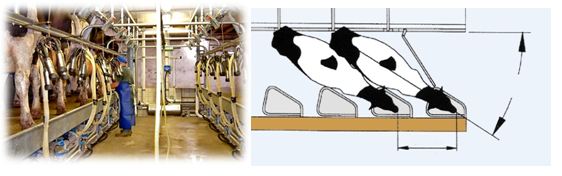

The 32°

In the 32° parlour the teat cups can be applied from the side or between the cow's rear legs.

Both the 50° and 32° herringbone parlours can be used with either the Streamline or Cleanline systems

Streamline

Streamline is a high capacity milking system for new or existing parlours.

Cleanline

The Cleanline system is an all-enclosed design in stainless steel that transforms the milking parlour. Specially constructed housing protects the essential milking equipment against soiling and contamination. This housing encases equipment such as milk meters, pulsators and pipework beneath the cow platform with similar stainless steel enclosures surrounding overhead milking stations above the kick rail.

The new design could potentially save on labour, as the flatter surfaces are easier and quicker to wash down. Specially constructed sliding doors in the cabinets beneath each milking station allow easy access to equipment for maintenance or taking milking samples.

Parallel Parlour

The main features of this milking system are:

- A parallel rapid exit parlour designed for high throughputs

- The unit provides individual indexing of the cows ensuring optimum udder presentation

- Gravity controlled indexing gates hold the animals in position whilst being milked then lift up and out of the way to allow them to exit

- These gates can be opened individually to release a cow for treatment or segregation

- Sequence gates between the cows allow cow to cow contact putting nervous animals at ease.

- The animals can clear the stalls in seconds overcoming slow transfer

- Is fully integrated with Fullwood Crystal herd management software

Resulting in many benefits for the farmer:

- High throughput will reduce overall milking time

- Safe, clean conditions for hygienic milk production

- Quiet stress-free environment

This parlour can also be fitted with the Cleanline system design.

To see a Fullwood Index 90 in action, watch the video.

To see how some of our Index 90 farmers are getting on, please click here

Goat and Sheep Parlours

Fullwood has a complete range of stalling suitable for small ruminants, from static systems and rapid exits, to swing over parlours and large rotaries, with or without feeding. Our largest rotary can milk up to 1000 goats or sheep per hour.

Fullwood has a full range of milking equipment specifically designed for the very different udder configurations of both goats or sheep. Whether you require a simple cluster remover, or a complete auto ID system with milk meters linked to Crystal, the herd management software, Fullwood has the solution, all designed in-house.

Portable Milking

Portable Milker 70084